The Typical Efficiency Of A Motor

- Xie

- Jul 28, 2025

- 8 min read

Understanding Motor Efficiency: A Comprehensive Overview

Motor efficiency analysis is essential for optimizing energy use in various applications. By examining a motor's efficiency, industries can significantly reduce energy costs and environmental impact. Understanding how motors convert electrical energy into mechanical energy involves investigating their design, operation, and performance. Through close scrutiny, we can identify potential issues and areas for improvement, ultimately leading to enhanced productivity.

Importance of Motor Efficiency

Evaluating motor efficiency is pivotal in sectors such as manufacturing and transportation. Inefficient motors can lead to excessive energy consumption, which not only burdens operational costs but also increases carbon footprints. By conducting a thorough motor efficiency analysis, organizations can ensure optimal performance, thereby saving money and promoting sustainability.

Factors Affecting Motor Efficiency

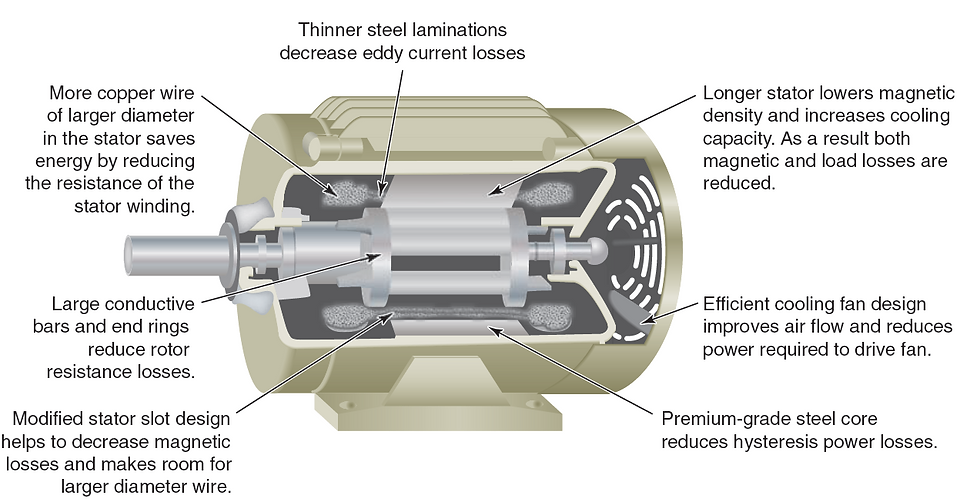

Several factors influence motor efficiency, including load conditions, ambient temperature, and maintenance practices. Understanding these elements is crucial to improving overall efficiency. Regular maintenance, proper alignment, and the use of high-quality components can dramatically enhance motor performance, leading to significant operational savings.

Regular Maintenance

Proper Load Management

Quality Components

Temperature Monitoring

Implementing these strategies not only promotes better performance but also extends the life of the motor.

Motor Type | Typical Efficiency (%) |

AC Induction Motor | 85-95 |

DC Motor | 80-90 |

Stepper Motor | 70-85 |

Conclusion

Efficient energy management is increasingly important. By prioritizing motor efficiency analysis and applying best practices, businesses can achieve significant operational upgrades.

Explore more insightful articles like this one – we have plenty more for you to discover here!

Conduct regular motor audits

Implement energy-saving technologies

Train staff on best practices

“Investing in motor efficiency analysis not only boosts performance but is vital for sustainable development.”

Key Factors Influencing Motor Performance Evaluation

Motor efficiency analysis plays a crucial role in understanding how well various factors impact an individual's ability to perform motor tasks. Evaluating these factors can provide insights into physical capabilities and limitations. By closely examining the underlying principles of performance evaluation, practitioners can better tailor training programs and interventions that enhance motor function, leading to improved outcomes.

Physical and Environmental Conditions

One of the primary considerations in motor efficiency analysis is the influence of physical and environmental conditions. Factors such as temperature, humidity, and surface type can significantly affect performance. Understanding these variables allows athletes and coaches to create optimal training environments and conditions that enhance motor efficiency.

Biomechanical Alignment

Biomechanical alignment is another essential component impacting motor performance evaluation. The body's structural alignment affects how efficiently movements are executed. Proper biomechanical analysis can identify misalignments or inefficiencies, allowing for targeted adjustments to improve overall motor performance.

Muscle strength

Skill level

Coordination

Fatigue levels

Equipment used

Factors | Impact on Performance |

Muscle Strength | Improves force output |

Coordination | Affects movement fluidity |

Fatigue | Reduces effectiveness |

Conclusion

Incorporating a comprehensive motor efficiency analysis can significantly improve performance evaluations. Understanding key influencing factors, such as physical conditions and biomechanical alignment, is essential for any training regimen.

Evaluate environmental conditions

Assess alignment regularly

Monitor strength and fatigue levels

“Motor efficiency analysis is critical for tailoring training strategies that align with an athlete's unique needs.”

Step-by-Step Guide to Conducting Motor Efficiency Assessments

Motor efficiency analysis is crucial for optimizing machine performance and energy consumption. This step-by-step guide outlines the essentials of conducting a thorough assessment. Understanding the efficiency of your motors not only enhances productivity but also contributes to substantial energy cost savings. With the right approach, you can identify inefficiencies and implement effective solutions.

Preparation for the Assessment

The initial phase of any motor efficiency analysis begins with comprehensive preparation. Gather all relevant motor specifications, historical data, and operational metrics. This data will serve as a foundation for your evaluation. Additionally, ensure you have the necessary tools and instruments to measure factors like power consumption, load, and output efficiency.

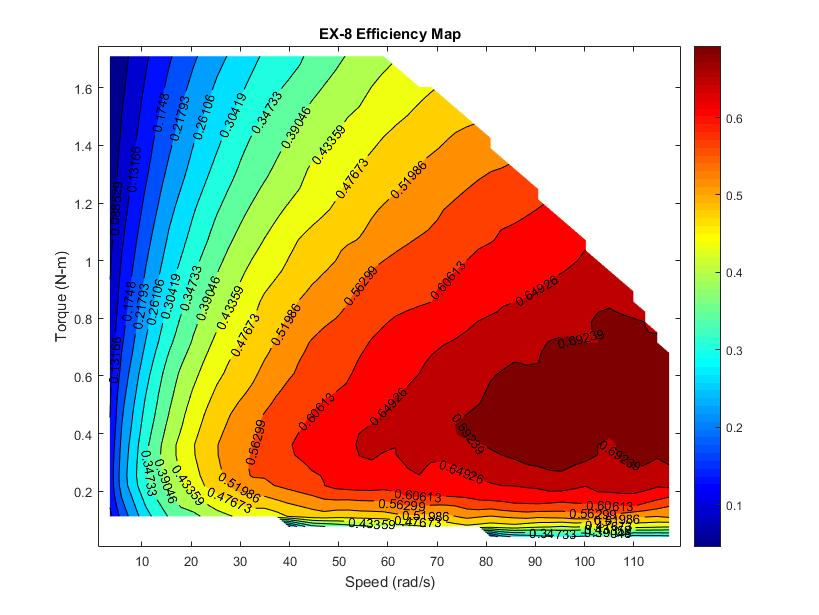

Conducting Measurements

Once prepared, it's time to conduct your measurements. Start by assessing the input power of the motor and the output mechanical power. Collecting accurate data is essential for a correct analysis. Employ precise instruments to measure voltage, current, and speed. Document all findings meticulously to aid in further analysis.

Check motor voltage and current.

Measure speed and torque output.

Calculate the efficiency using the formula: Efficiency = (Output Power/Input Power) x 100%.

Input Power (kW) | Output Power (kW) |

20 | 18 |

Implementing Improvements

After completing the motor efficiency analysis, take action based on your findings. Design and execute a plan to address any identified inefficiencies, whether through maintenance, upgrades, or operational adjustments.

Regular maintenance and lubrication.

Replacing worn components.

Optimizing operational settings.

“Enhancing motor efficiency significantly reduces operational costs and carbon footprints.”

Explore more insightful articles like this one – we have plenty more for you to discover here!

Benefits of Improved Motor Efficiency for Businesses

Understanding motor efficiency analysis is crucial for businesses aiming to reduce operational costs and enhance productivity. By investing in improved motor efficiency, companies can experience a range of benefits including reduced energy consumption and lower maintenance costs. The analysis provides valuable insights into how machinery is performing, enabling businesses to make informed decisions that lead to financial savings and increased longevity of equipment.

If you have any questions or are interested in our products, feel free to contact us

Cost Savings and Sustainability

One of the primary benefits of motor efficiency analysis is the potential for significant cost savings. Efficient motors consume less energy, reducing electricity bills dramatically. Moreover, less energy consumption contributes positively to sustainability efforts, allowing businesses to meet environmental goals while cutting costs. An energy-efficient operation also enhances a company’s reputation among eco-conscious consumers.

Enhanced Operational Performance

Improved motor efficiency not only saves money but also enhances overall operational performance. When machines operate at their optimal efficiency, downtime is reduced, and production rates increase. Regular motor efficiency analysis can identify underperforming equipment, leading to proactive maintenance and increased uptime, ensuring that businesses remain competitive in their industries.

Future Growth Opportunities

Motor efficiency analysis paves the way for future growth opportunities. As technologies evolve, businesses that adopt efficient practices will be better positioned to adapt and thrive. This analysis not only presents a path to cost reduction but also encourages continuous improvement in technology adoption.

Investing in motor efficiency analysis is not just about saving money; it’s about pioneering a path toward innovation and sustainability in the industry.

Common Challenges in Motor Efficiency Measurement

Motor efficiency analysis plays a crucial role in optimizing energy consumption and enhancing performance in various industrial applications. However, accurately assessing motor efficiency can be fraught with challenges. Factors such as measurement errors, inconsistent testing conditions, and the need for accurate data collection often complicate the process. Furthermore, variations in standards for efficiency testing can lead to discrepancies in results, making it difficult to establish a reliable baseline for comparison. Here is our homepage

Measurement Errors

One of the primary hurdles in motor efficiency analysis is measurement errors. Often, these errors can stem from faulty equipment or techniques, resulting in inaccurate data. Precise measurements are necessary to gauge motor performance effectively, which requires high-quality instruments and methodologies. Without robust measurement practices, it's nearly impossible to trust the efficiency data collected, leading to potentially poor decision-making.

Inconsistent Testing Conditions

Inconsistent testing conditions can also skew results. Changes in temperature, humidity, or electrical supply can all notably affect motor performance. Maintaining standardized conditions during tests is essential for achieving reliable outcomes. By minimizing these inconsistencies, industry professionals can obtain data that is reflective of true motor efficiency.

Outdated testing equipment

Varying environmental conditions

Lack of standardized procedures

Data integrity issues

Challenge | Description |

Measurement Errors | Issues arising from faulty instruments or techniques. |

Inconsistent Conditions | Variations in environment affecting results. |

Final Thoughts

Thorough motor efficiency analysis is crucial for operational success. By tackling common challenges, organizations can achieve more precise measurements and improve energy use.

Emphasizing accurate data collection

Implementing standardized testing protocols

"Investing in thorough motor efficiency analysis can lead to substantial long-term savings and performance enhancement."

Future Trends in Motor Performance Analysis Techniques

Motor efficiency analysis is set to revolutionize our understanding of performance across various industries. With advancements in technology, we now have better tools and methods to dissect motor operations. This analysis not only enhances energy efficiency but also ensures that motors operate effectively under varying conditions. The future will likely focus on incorporating AI and machine learning algorithms, enabling deeper insights into performance metrics that were once elusive.

Integration of Real-Time Data

The use of real-time data in motor efficiency analysis will become increasingly important. Sensors embedded in motors will provide continuous feedback, allowing for immediate adjustments to enhance performance. By analyzing these data streams, engineers can predict failures before they occur, saving both time and resources. This proactive approach to motor analysis leads to improved reliability and longevity of equipment.

Advanced Simulation Models

Future trends point towards the development of advanced simulation models that mimic various operational scenarios. These models will allow engineers to test motor efficiency in a virtual environment, exploring countless variables without the high costs associated with real-world testing. This methodology not only accelerates the design process but also enhances the overall quality of products on the market.

Real-time sensor integration

AI-powered predictive analytics

Virtual simulation testing

Customized motor design

The continual evolution of motor efficiency analysis will ensure that industries can maximize their output while minimizing waste. By staying ahead of these trends, organizations will not only enhance their operational efficiency but also contribute to sustainability goals in an increasingly eco-conscious landscape.

Trend | Description |

Real-Time Integration | Continuous feedback loops for immediate adjustments. |

AI Analytics | Predictive analytics to forecast motor failures. |

Simulation Models | Testing environments without physical prototypes. |

Future Potential

As we look toward the horizon, it's clear that the realm of motor efficiency analysis is rich with possibilities. Integration of cutting-edge technologies and methodologies will empower industries to enhance motor performance significantly. As these innovations take hold, we can expect a significant paradigm shift in how motors are designed, maintained, and utilized.

Innovative motor designs

Enhanced sustainability practices

Increased operational efficiency

"The advancements in motor efficiency analysis will not just redefine operational norms but will also pave the path towards a sustainable industrial future."

FAQs: Your Questions on Motor Efficiency Analysis Answered

Motor efficiency analysis is crucial for understanding how well your equipment performs. This analysis can help you to identify areas needing improvement, ultimately leading to cost savings and enhanced performance. By understanding the factors that contribute to motor efficiency, you can make informed decisions on maintenance and upgrades.

What is Motor Efficiency Analysis?

Motor efficiency analysis evaluates how well a motor converts electrical energy into mechanical energy. This process is fundamental in various industries, resulting in optimized operational practices. Keeping track of efficiency metrics helps companies ensure they are using energy resources effectively, which is essential for both sustainability and budget management.

How can I improve motor efficiency?

Several methods can enhance motor efficiency in your operations. Implementing regular maintenance schedules, utilizing advanced motor technologies, and monitoring performance metrics can have significant impacts on efficiency levels. Moreover, upgrading to higher-quality components can also lead to improved operational effectiveness.

Regular maintenance checks

Upgrade to energy-efficient motors

Monitor performance regularly

These actions help maintain optimal performance, reduce energy consumption, and prolong the lifespan of your motors.

Efficiency Factor | Impact on Performance |

Maintenance | Ensure optimal functioning and longevity |

Upgrades | Increased efficiency and reduced energy consumption |

Why is motor efficiency analysis important?

Motor efficiency analysis is vital not only for reducing operational costs but also for improving productivity. Efficient motors use less energy, which directly correlates with lower utility bills and enhanced environmental stewardship. Businesses aiming for sustainability and cost-effectiveness must prioritize this analysis.

Lower energy costs

Reduced carbon footprint

Improved operational performance

Investing in motor efficiency analysis pays off significantly, leading to substantial benefits for your business.

Comments