The Ultimate Guide to High-Speed DC Motor Control for Industrial Automation

- Xie

- Jul 16, 2025

- 10 min read

Understanding High Speed DC Motors: A Key Component in Industrial Automation

High-speed DC motors play an essential role in the realm of industrial automation. These precision speed control motors are renowned for their ability to deliver high torque and rapid response times, making them ideal for applications that require quick adjustments and reliable operation. Imagine a machine that can fine-tune its speed in real-time—this is the magic of a high-speed DC motor. Whether it's a conveyor belt, robotic arm, or an assembly line, these motors can handle diverse demands with ease.This is just one of many great blogs we have—explore more right here.

Precision Speed Control in Action

One of the standout features of high-speed DC motors is their precision speed control capabilities. With the right control mechanisms, operators can achieve ultra-fine adjustments to speed outputs, ensuring that every motion is executed flawlessly. This kind of precision is particularly beneficial in sectors like manufacturing and packaging, where timing is everything. Have you ever watched a robotic arm at work? It’s a dance of speed and accuracy, all thanks to these motors.

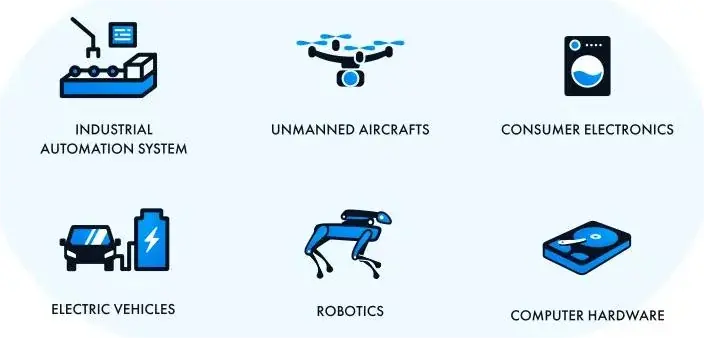

Common Industrial DC Motor Applications

Let’s explore some common applications for high-speed DC motors:

Robotics Automation

Textile Machinery

Printing Equipment

Material Handling

Medical Devices

Application | Motor Type | Typical Speed Range (RPM) |

Robotics | High-Speed DC Motor | 3000-8000 |

Textile Machines | Precision Speed Control Motor | 1500-3500 |

High-speed DC motors truly are the unsung heroes within industrial automation. When you consider their importance, it's no surprise that industries are increasingly leaning towards these incredible components. They bring reliability and efficiency, and let’s face it, who doesn’t want that?

In the world of industrial automation, high-speed DC motors are not just components; they are the beating heart of efficiency.

Precision Speed Control: How It Enhances Performance in Industrial DC Motor Applications

Have you ever wondered why precision speed control is a game changer in industrial DC motor applications? I’m talking about high-speed DC motors that require not just power but finesse in control. When we dive into the world of precision speed control motors, we unveil the capabilities that can optimize production lines and drive efficiency to new heights. Imagine a high-speed DC motor that can match the pace of your most demanding tasks without compromising on performance or accuracy. Sounds revolutionary, right?

The Mechanics Behind Precision Speed Control

Understanding how precision speed control works is like unlocking a hidden door to better industrial performance. By managing voltage and current effectively, we can manipulate the speed of DC motors with pinpoint accuracy. This means your machinery doesn’t just run faster; it runs smarter. In applications ranging from conveyor systems to machine tools, the benefits are palpable. Every wobble eliminated leads to increased productivity. Every missed beat avoided translates to longer equipment lifespan.

Advantages of Implementing Precision Speed Control

So, what makes precision speed control motors a must-have? Here are a few compelling advantages:

Enhanced efficiency in high-speed operations

Reduced energy consumption

Improved operational lifespan

Consistent output quality

Not only does this precision translate into better speed, but it also contributes to safer work environments and lower maintenance costs in the long run. Here's a quick comparison table to visualize the differences:

Motor Type | Efficiency | Application Suitability |

High-Speed DC Motor | 90%+ | Robotics, Conveyor Systems |

Standard DC Motor | 70%-80% | Basic Machinery |

Innovation in Action

With precision speed control, industries are reshaping their operational capabilities. Production lines aren't just faster; they’re agile. But how do manufacturers start integrating this revolutionary technology? The pathway is clearer than you think.

Research current motor specifications

Consult with technical experts

Pilot test precision speed control in small areas

“Adopting precision speed control in our operations wasn't just an upgrade; it was a transformation.”

Practical Applications of High Speed DC Motors in Various Industries

High-speed DC motors have revolutionized numerous industrial sectors by providing exceptional precision and control. These workhorses of automation excel in environments requiring the precise speed control that traditional motors simply cannot provide. Industries from manufacturing to robotics increasingly rely on high-speed DC motors, particularly for tasks that demand speed adjustments and quick reactions. When it comes to the functionality and efficiency of industrial DC motor applications, these motors lead the charge, making them indispensable in today’s tech-driven world.

Manufacturing

In manufacturing, high-speed DC motors play a vital role, particularly in conveyor systems and assembly lines. The precision speed control motor capabilities ensure seamless transitions between different tasks, enhancing productivity. Imagine a conveyor belt that can instantly adapt to varying loads and speeds; this adaptability significantly reduces downtime, maximizing output. Decisions about the types of motors to use can impact efficiency and product quality tremendously.

Robotics

Robotics is another domain where high-speed DC motors shine. In robotic arms, high-speed DC motors enable intricate movements and exact positioning, critical for delicate tasks like assembly and surgery. The precision inherent in these motors allows robots to replicate complex human motions, resulting in more advanced automated systems that are both reliable and efficient.

Conveyor systems: Fast and variable speed adjustments

Robotic arms: Precision and accuracy in movement

Pumps and fans: Adaptable speed for energy efficiency

Here is a table outlining some use cases and their associated efficiency gains:

Application | Efficiency Gain |

Conveyor Systems | 20-30% |

Robotics | 15-25% |

Pumps & Fans | 10-20% |

Other Industries

Beyond just manufacturing and robotics, high-speed DC motors find use in various industries like automotive and healthcare. As the demand for automation crosses traditional boundaries, understanding this technology can open up innovative applications that enhance productivity. Industries are continually exploring how high-speed DC motors can redefine their operations.

Automotive: Electric vehicles and automated assembly lines

Healthcare: Precision devices and surgical instruments

Aerospace: Efficient flight control systems

"High-speed DC motors are not just motors; they are the backbone of modern automation, enabling real-time control and adaptability."

Components of Precision Speed Control Motors: What You Need to Know

Welcome to the world of high-speed DC motors! These specialized devices are at the heart of modern industrial automation, playing critical roles in everything from conveyor belts to robotic arms. But what truly sets a precision speed control motor apart from regular motors? Let's dive into the essential components that make them a powerhouse for industrial DC motor applications.Want to explore more? Head over to our homepage and see what we have to offer!

The Basics of Speed Control

Understanding speed control starts with knowing the key components involved. Precision speed control motors typically include a robust feedback mechanism and a controller. The feedback gives real-time data, allowing the controller to adjust power delivery and maintain the desired speed. It’s a dance of electronics, where accuracy means everything.

The Role of Feedback Loops

Feedback loops are crucial for ensuring that your high-speed DC motor operates within parameters. They monitor speed and make instantaneous adjustments, which is vital for maintaining efficiency and performance. This real-time communication prevents slip and helps achieve smooth operation in various industrial applications.

High responsiveness to changes in load

Enhanced energy efficiency

Increased operational longevity

Feature | Benefits |

Feedback Mechanisms | Real-time speed adjustments |

Specialized Controllers | Enhanced control over motor performance |

Real-World Applications

Imagine the precision required in an automotive assembly line. High-speed DC motors aren't just powering machines; they’re orchestrating intricate tasks with utmost precision. It's these motors that ensure optimum throughput and quality in mass production settings.

Robotics

Textile machinery

Food processing equipment

“High-speed DC motors are the silent heroes of industrial automation, operating quietly but efficiently behind the scenes.”

Benefits of High Speed DC Motors in Automation Systems

In the ever-evolving landscape of industrial automation, high speed DC motors shine with incredible benefits tailored for precision applications. As we push for speed and accuracy in manufacturing processes, the role of a precision speed control motor has never been more crucial. From robotics to conveyor belts, these motors offer an unmatched level of responsiveness, making them indispensable in various industrial DC motor applications.

Enhanced Responsiveness and Control

One of the undeniable benefits of high speed DC motors is their enhanced responsiveness. Unlike traditional AC motors, these DC motors allow for fine-tuned adjustments at high speeds. Imagine needing to alter the rotation speed of a robotic arm mid-operation; with a high speed DC motor, you can seamlessly adapt to real-time demands without skipping a beat. This capability can significantly reduce the risk of errors during manufacturing processes.

Energy Efficiency

Energy efficiency is another vital advantage. High speed DC motors require less energy to operate compared to their counterparts while delivering high performance. This is not just about cutting costs; it’s also about creating sustainable industrial practices. With lower energy consumption, facilities can reduce their carbon footprint, aligning with broader corporate sustainability goals.

High-precision control

Fast acceleration and deceleration

Robust design

Versatile applications

Considering the diverse applications, it’s essential to choose the right motor specifications. The table below outlines key parameters that should influence your selection process:

Parameter | Standard Range | High-Speed DC Motor |

Speed (RPM) | 1000-5000 | Up to 20000 |

Torque (Nm) | 0.5-5 | Up to 10 |

Voltage (V) | 24-48 | Up to 60 |

Operational Versatility

With their wide operational versatility, high speed DC motors cater to industries from automotive to textiles. They provide reliable performance across various applications, making them a go-to choice for engineers and manufacturers alike.

Robotic arms

Automated conveyors

3D printers

“High speed DC motors are not just components; they are the beating heart of modern automation.”

Troubleshooting Common Issues in Precision Speed Control Motors

When working with high-speed DC motors, particularly in industrial DC motor applications, you might encounter several challenges. Understanding these common issues is crucial for effective precision speed control. Often, unanticipated motor behavior stems from electrical noise, improper feedback loops, or even misconfigured drive settings. Take a moment to consider what might be going wrong in your setup. Could it be an issue with power supply fluctuation, or perhaps the encoder isn't communicating effectively with the motor controller? Each aspect plays a role in the smooth operation we expect.

Identifying Electrical Noise Problems

Electrical noise can significantly impact precision speed control. Symptoms may include erratic speed fluctuations or a motor that won't start at all. The root causes can vary; for example, improper grounding or close proximity to other electrical devices. I've often found that adding filtering components can alleviate many of these issues. Don't overlook the potential disruption caused by external electromagnetic fields, especially in industrial environments.

Feedback Loop Issues

The feedback loop is crucial for maintaining the desired speed in your high-speed DC motor. If you're noticing lag or overcorrection in your motor's movement, the problem could stem from improperly calibrated sensors or conflicting signals. Sometimes, a simple recalibration or upgrade of the sensor can enhance performance dramatically. Be sure to check all connections and settings!

Power supply fluctuations

Improper sensor calibration

Magnetic interference

Issue | Solution |

Erratic Speed | Check electrical connections and shielding |

Motor Won't Start | Inspect power supply and feedback settings |

The right troubleshooting can turn a complex problem into a simple fix.

Future Trends in High Speed DC Motor Technology for Industrial Applications

As we venture into the future of industrial automation, the role of high-speed DC motors is becoming increasingly pivotal. These precision speed control motors not only enable higher efficiency but also enhance responsiveness, making them ideal for a variety of industrial DC motor applications. Imagine a world where manufacturing processes are not only faster but also more precise, thanks to innovations in motor technology. With advancements like improved magnetic materials and smart electronics, the capabilities of these motors are evolving at an incredible pace.

Enhancements in Control Algorithms

Marvel at the transformative potential of control algorithms! The development of advanced algorithms allows for better management of torque and speed, creating a new paradigm for precision speed control motors. This is crucial in industries that demand meticulous accuracy, where even a slight deviation can lead to catastrophic failures. By integrating machine learning, we can fine-tune motor responses to real-time data inputs, paving the way for smarter automation.

Energy Efficiency Initiatives

Energy efficiency is no longer an option; it's a necessity. With rising energy costs and environmental concerns, many industrial applications are leaning toward high-speed DC motors with optimized energy consumption. Manufacturers are maximizing the operational efficiency of these motors, making them not just fast but also sustainable.

Adaptive control methods

Integration with IoT technologies

Enhanced thermal management

These trends point to a future where high-speed DC motor technology is streamlined for even greater efficiency and adaptability.

Feature | Traditional Motors | High-Speed DC Motors |

Speed Range | Low | High |

Control Precision | Standard | Advanced |

Energy Efficiency | Moderate | High |

Looking Beyond Conventional Designs

As we look ahead, it's essential to recognize the need for both flexibility and scalability in high-speed DC motor designs. Industries are shifting towards custom solutions that fit their unique requirements. This means there's a growing emphasis on modular designs, enabling modifications as necessary without a complete overhaul of existing systems.

Modular architectures

Customized speed profiles

"The future of industrial applications lies in motors that adapt as quickly as the market demands."

Conclusion: Maximizing Efficiency with High Speed DC Motors

When it comes to industrial automation, choosing the right tools can make all the difference. High-speed DC motors stand at the forefront, offering precision speed control that few can match. These motors aren't just about speed; they deliver torque and responsiveness that transform workflow efficiency. If you've ever wrestled with inconsistent motor performance, you know how vital it is to have reliable equipment. As industries pivot to more automated systems, high-speed DC motors become essential in ensuring operations run smoothly and efficiently.

Understanding the Applications

High-speed DC motors are invaluable across various industrial applications like robotics, conveyor systems, and pumps. They not only provide quick acceleration but also allow for seamless integration with modern control systems. Precision speed control motors maintain tight tolerances, making them ideal for tasks requiring a delicate touch. This versatility means that these motors can adapt to fluctuating demands, ensuring time-sensitive operations are met without compromising quality. With more industries focusing on automation, today's engineers must familiarize themselves with these motors to stay competitive.

Key Advantages of High-Speed DC Motors

The advantages are compelling. Here’s a taste:

Enhanced speed control capabilities.

Lower maintenance needs due to fewer mechanical components.

High reliability in demanding operational environments.

But that's not all. The efficiency gains often lead to reduced energy costs, a crucial factor for any industrial application.

Feature | Benefit |

High-speed performance | Improved productivity |

Precision control | Enhanced product quality |

Durability | Lower total cost of ownership |

Lighting the Path Forward

As we look to the future, embracing high-speed DC motors is not just beneficial; it’s nearly mandatory. This technology paves the way for smarter operations and smarter solutions.

Innovation in automation.

Scaling production with ease.

Meeting higher quality standards.

"A revolution in performance: with high-speed DC motors, we are not just keeping up; we’re setting the pace."

FAQs About High Speed DC Motors and Their Applications

When diving into the realm of high-speed DC motors, it's crucial to understand their pivotal role in industrial automation. These motors boast remarkable acceleration capabilities, making precision speed control a breeze. Ideal for various applications, they offer unmatched performance in tasks requiring rapid responses and fine-tuned operational demands.If you have any questions or are interested in our products, feel free to contact us.

What makes high-speed DC motors special?

High-speed DC motors stand out due to their efficiency and adaptability. Their design allows for quick adjustments in speed, helping industries maintain the delicate balance required for intricate processes. For instance, assembly lines benefit hugely from this feature, as the precision speed control motor can be adjusted on-the-fly to enhance productivity without sacrificing quality.

How are these motors applied in industry?

Industrial DC motor applications are vast and varied, spanning from robotics to conveyor systems. Their versatility ensures that whether you're in manufacturing or food processing, a high-speed DC motor can meet your needs. Below are a few noteworthy applications:

Robotic arms for precise manipulation

3D printers requiring intricate speed control

Automated packaging machinery

Curious to understand how these motors operate? Here's a concise overview:

Motor Type | Typical RPM | Common Applications |

High-Speed DC Motor | Up to 20,000 | Turbines, Pumps |

Precision Speed Control Motor | Varies | Conveyor Systems, Robotics |

Common misconceptions about high-speed DC motors

Many believe that high-speed motors are only for advanced technologies, but they are essential even in everyday devices. Their robust nature allows them to power critical applications across sectors.

Not just for high-tech applications

Can be cost-effective

Reliable and user-friendly

Comments