What Are Ie1, Ie2, And Ie3 Motors?

- Xie

- Jul 28, 2025

- 9 min read

Understanding IE1, IE2, IE3 Electric Motors

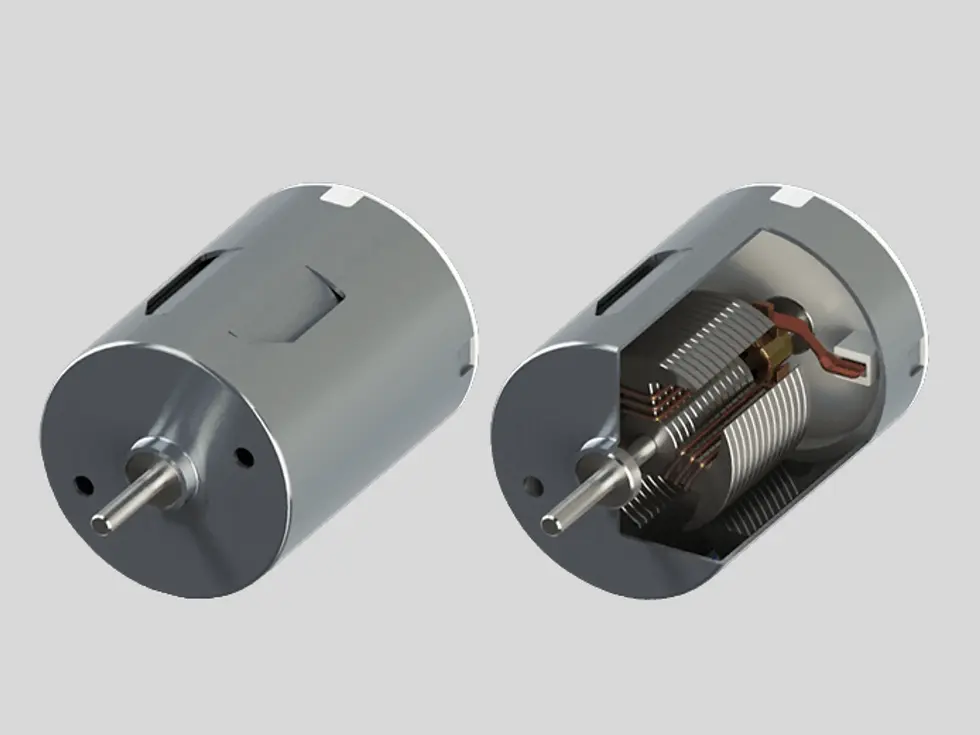

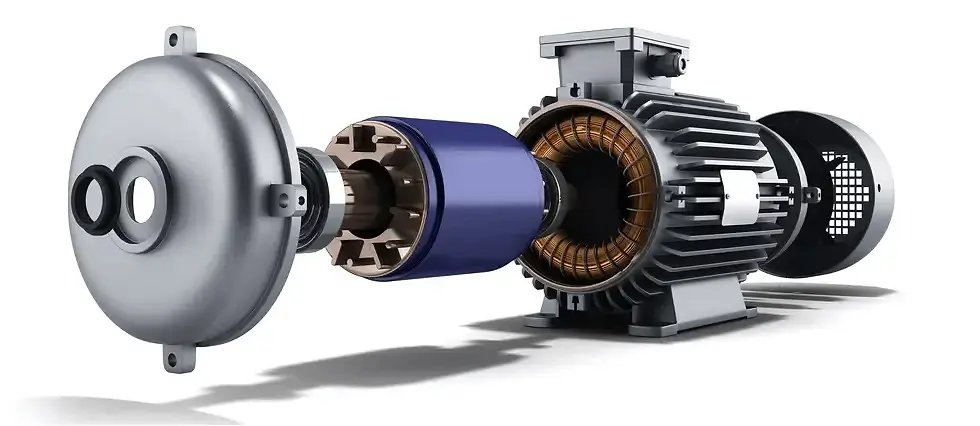

IE1, IE2, and IE3 motors represent a classification system that measures energy efficiency in electric motor designs. These classifications, defined by the International Electrotechnical Commission (IEC), indicate how effectively motors convert electrical energy into mechanical energy. For industries looking to optimize energy consumption, understanding these motor types is essential for compliance with energy efficiency regulations and reducing operational costs.

IE1 Motors

IE1 motors, while they offer basic efficiency, fall short of modern energy standards. They are typically used in simple applications where energy savings are not a concern. As industries move toward sustainability, the reliance on IE1 motors is diminishing. Selecting these motors might seem cost-effective initially, but they can result in high operational costs over time due to inefficiency.

To meet the ultimate in efficiency and responsiveness in modern applications, many engineers and designers are turning to more specialized powertrains. If you're looking for a drive solution that combines speed and stability, the Speed-focused Motor is the ideal choice. It not only improves overall operating efficiency, but also demonstrates superior acceleration and precise control in mission-critical applications.

IE2 Motors

IE2 motors are a step up from IE1, providing improved efficiency levels. These motors are suitable for a variety of industrial applications and deliver a better return on investment thanks to their reduced energy consumption. Businesses that upgrade to IE2 can enjoy significant savings on electricity bills, making them a favorable choice for operators seeking to balance performance with eco-friendliness.

Cost-effective option for certain applications

Initial investment may be lower

Basic efficiency performance

However, advancements like IE3 motors are outpacing IE2 in terms of efficiency.

Motor Type | Efficiency Rating | Usage |

IE1 | Standard | Low-demand applications |

IE2 | Enhanced | Moderate-demand applications |

IE3 | High | High-demand applications |

IE3 Motors

IE3 motors represent the top tier of energy efficiency, designed for high-performance applications. They offer optimal energy savings and are becoming increasingly popular as industries aim to comply with strict energy regulations. Businesses investing in IE3 motors not only reduce their carbon footprint but may also benefit from government incentives for sustainable practices.

In many applications where high load capacity is required, high speed is not enough. A drive solution with strong torque output is the key, and the Torque -focused Motor is designed to cope with high loads and high resistance environments, and maintains a stable and strong power output at low speeds, which is widely used in industrial automation, heavy machinery, and lifting and lowering systems in the smart home.

Best efficiency ratings

Significant energy savings

Ideal for high-demand industries

"Investing in IE2 and IE3 motors is not just about compliance; it's also about embracing a sustainable future."

Key Advantages of IE1, IE2, IE3 Motor Classes

Understanding the advantages of different motor classes is crucial for anyone involved in industrial applications. IE1, IE2, and IE3 motors stand out due to their energy efficiency and performance. The primary distinction between these classes lies in their efficiency ratings. While IE1 motors are the most basic, IE2 and IE3 motors dominate due to their superior design, yielding enhanced operational savings and longevity. This makes them ideal for various applications where energy consumption is a concern.

Energy Efficiency

IE2 and IE3 motors offer significant energy savings compared to their IE1 counterparts. For instance, IE3 motors can provide up to 10-20% higher efficiency levels, meaning that industries can save thousands annually on energy costs. This makes IE2 and IE3 motors not just a cost-effective option but a sustainable one, promoting environmental responsibility by reducing overall energy consumption.

Durability and Longevity

The advanced engineering of IE2 and IE3 motors enhances their durability, leading to fewer breakdowns and maintenance requirements. As a result, businesses can operate more smoothly and avoid costly downtimes. This translates to not only operational efficiency but also less environmental impact from mechanical failures.

IE1 Motors: Basic efficiency and lower cost.

IE2 Motors: Moderate efficiency with improved energy savings.

IE3 Motors: Top-tier efficiency, high savings potential.

Motor Class | Efficiency (%) | Typical Use |

IE1 | Up to 85% | Basic applications |

IE2 | Up to 88% | General purpose |

IE3 | Up to 91% | Advanced applications |

Final Thoughts

Choosing the right motor class can significantly impact operational efficiency. By investing in IE2 or IE3 motors, businesses are not only opting for higher performance but also contributing to a more energy-efficient future.

Boost energy savings with higher motor efficiency.

Reduce operational costs over time.

Contribute to environmental sustainability.

"Investing in IE2 and IE3 motors not only benefits your bottom line but also takes a step towards sustainability and eco-conscious operations."

How to Choose the Right IE1, IE2, IE3 Motor

Selecting the appropriate IE1, IE2, IE3 motors can significantly impact your operational efficiency. These motors categorize energy efficiency based on performance. The choice hinges on various factors including application requirements, energy consumption, and budget constraints. Understanding these categories allows users to make informed decisions that enhance productivity and cost-effectiveness.

Assessing Your Application Needs

Your first step in choosing between IE1, IE2, and IE3 motors is to assess your specific application needs. Consider the operational environment, load requirements, and desired performance level. For example, if your equipment operates continuously and requires higher efficiency, an IE3 motor might be optimal. Understanding these needs is essential for selecting the right motor that aligns with your operational goals.

Evaluating Energy Consumption

Next, consider the energy consumption associated with each motor type. The IE2 and IE3 motors offer improved energy savings, which can lead to substantial cost reductions over time. By calculating the total energy costs and projecting future savings, you can justify the investment in a more efficient motor. Awareness of energy consumption trends will guide your selection process effectively.

Determine load requirements

Assess environmental conditions

Calculate energy costs

Motor Type | Efficiency Level | Common Applications |

IE1 | Standard | General Industrial |

IE2 | High | HVAC, Pumps |

IE3 | Premium | Continuous Duty |

Considering Budget Constraints

Finally, factor in your budget when selecting IE1, IE2, IE3 motors. While the initial cost of IE3 motors may be higher, their long-term savings could result in a better investment overall. Use cost-benefit analyses to compare potential energy savings against the purchase price.

Explore more insightful articles like this one – we have plenty more for you to discover here !

Initial cost evaluation

Long-term operational savings

Consider financing options

Investing in the right motor type not only enhances efficiency but can also lead to cost reductions in the long run. Choose wisely!

Energy Efficiency Ratings of IE1, IE2, IE3 Motors

The energy efficiency of electric motors plays a crucial role in reducing operational costs and environmental impacts. Various ratings, such as IE1, IE2, and IE3 motors, define their efficiency standards. Each of these classifications indicates a different level of energy consumption and performance, enabling industries to make informed decisions. Understanding these ratings is critical for businesses aiming to optimize energy usage and embrace sustainability.

Understanding IE1 Motors

IE1 motors represent the lowest efficiency class within the International Electrotechnical Commission (IEC) framework. While they may be less expensive initially, they consume more energy over time, leading to increased operational costs. Businesses using IE1 motors might benefit in the short term but face higher costs long-term due to energy waste.

Getting to Know IE2 Motors

IE2 motors offer a better efficiency rating than IE1. Although they require a larger upfront investment, IE2 motors significantly reduce energy consumption by approximately 5-10%. This improved efficiency not only lessens operational costs but also caters to industries striving for sustainability.

IE1: Basic performance, high energy consumption

IE2: Moderate efficiency improvements

IE3: Advanced technology with optimal energy savings

With increasing demand for energy conservation, IE3 motors have emerged as the most efficient option. They are designed for high-performance applications and can save up to 20% in energy usage compared to IE1 motors.

To meet the ultimate in efficiency and responsiveness in modern applications, many engineers and designers are turning to more specialized powertrains. If you're looking for a drive solution that combines speed and stability, the Speed-focused Motor is the ideal choice. It not only improves overall operating efficiency, but also demonstrates superior acceleration and precise control in mission-critical applications.

Motor Class | Efficiency (%) | Energy Savings |

IE1 | 75-80 | Standard |

IE2 | 80-85 | 5-10% |

IE3 | 85-90 | 20% |

Conclusion

Choosing the right motor can drastically affect energy consumption and efficiency. IE1, IE2, and IE3 motors cater to different energy needs and applications. For companies focused on cost-saving and eco-friendliness, opting for IE2 or IE3 models can lead to substantial long-term gains.

Explore more insightful articles like this one – we have plenty more for you to discover here !

Analyze operational needs

Consider upfront costs vs. long-term savings

Evaluate sustainability goals

“Investing in IE2 or IE3 motors is not just an expenditure but a strategic long-term saving method.”

In many applications where high load capacity is required, high speed is not enough. A drive solution with strong torque output is the key, and the Torque -focused Motor is designed to cope with high loads and high resistance environments, and maintains a stable and strong power output at low speeds, which is widely used in industrial automation, heavy machinery, and lifting and lowering systems in the smart home.

Applications for IE1, IE2, IE3 Electric Motors

IE1, IE2, and IE3 motors cater to a wide array of industrial applications, providing efficiency and reliability in operations. These motors are designed to perform across various sectors, contributing significantly to energy savings and operational performance. The classification of these motors allows industries to select the right motor based on their specific energy efficiency requirements, ensuring optimal performance and reduced energy consumption.

Industrial Manufacturing

In the realm of industrial manufacturing, IE1, IE2, and IE3 motors are extensively used for driving pumps, conveyors, and compressors. Their high efficiency translates into lower operating costs while ensuring consistent performance in heavy-duty applications. The choice of motor type often depends on the production needs and energy targets set by the facility.

Commercial Use

Commercial sectors utilize IE1, IE2, and IE3 motors for HVAC systems, refrigeration, and elevators. While IE1 motors might suffice for basic applications, the demand for greater energy efficiency typically leads businesses to opt for IE2 or IE3 models, achieving better long-term savings.

Manufacturing Equipment

Pumps and Compressors

HVAC Systems

Industrial Automation

Each motor class plays a crucial role in balancing efficiency with performance across varied applications, reinforcing sustainability in operations.

Motor Type | Efficiency Rating | Typical Applications |

IE1 | Standard | General machinery |

IE2 | High | Pumps, fans |

IE3 | Premium | Heavy industry, HVAC |

Energy and Environment

Using IE1, IE2, and IE3 motors not only supports energy efficiency but also aids in reducing carbon footprints. More businesses are recognizing their environmental responsibilities, opting for higher-efficiency motors to lessen energy consumption.

Lower emissions

Cost savings

Improved performance

Choosing the right motor can lead to significant savings, both financially and environmentally.

Future Trends in IE1, IE2, IE3 Motor Technology

The future of IE1, IE2, and IE3 motors is shaped by advances in efficiency, performance, and sustainability. As industries pivot towards energy-efficient solutions, the demand for these motors is increasing. The focus is on enhancing operational efficiency while reducing energy consumption, ensuring durability, and complying with stringent environmental regulations. New technologies are on the horizon that will revolutionize how we approach motor design and functionality.

Emerging Technologies

Emerging technologies in motor design, such as the integration of IoT and AI, are set to transform IE1, IE2, and IE3 motors. These technologies not only optimize performance but also provide real-time data for predictive maintenance. This leads to reduced downtime, maximizing productivity and decreasing operational costs. Companies are increasingly investing in smart motors equipped with sensors to leverage data analytics for enhanced performance.

Energy Efficiency Standards

Energy efficiency standards are evolving, and with them, the categorization of IE1, IE2, and IE3 motors. As new regulations such as the upcoming IE4 classification are introduced, manufacturers are compelled to innovate continuously. This shift will encourage the adoption of even more energy-efficient technologies, driving down emissions and costs, paving the way for sustainable industrial practices.

Integration of smart technologies

Compliance with updated energy standards

Focus on predictive maintenance

Enhancements in design for efficiency

Efficiency Class | Power Consumption | Typical Applications |

IE1 | Standard | General industrial use |

IE2 | High Efficiency | Electric vehicles, HVAC |

IE3 | Premium Efficiency | Heavy machinery, pumps |

Future Outlook

The outlook for IE1, IE2, and IE3 motors indicates a growth trajectory influenced by innovation and sustainability. Market leaders are likely to prioritize energy-efficient models that align with national and international standards, ensuring compliance with environmental policies.

Explore more insightful articles like this one – we have plenty more for you to discover here !

Growth in digitalization

Increased investments in R&D

Enhanced customer awareness about energy consumption

“The evolution of IE1, IE2, and IE3 motors not only represents a shift in technology but also a commitment to a more sustainable and efficient future.”

Frequently Asked Questions About IE1, IE2, IE3 Motors

When considering energy-efficient solutions, many manufacturers are turning to IE1, IE2, and IE3 motors. These motors are designed to provide varying levels of efficiency, catering to different industrial needs. Understanding the distinctions and applications of these motors is crucial for making informed decisions that enhance performance and reduce operational costs.

What is the difference between IE1, IE2, and IE3 motors?

IE1 motors are the standard efficiency while IE2 motors offer improved performance and reduced energy consumption. In contrast, IE3 motors are classified as premium efficiency, providing the highest energy savings and operational benefits. Transitioning from IE1 to IE3 can significantly lower energy bills over time.

How do I choose the right motor for my application?

Selecting the appropriate motor depends largely on your specific requirements, such as load, environmental conditions, and required efficiency. Utilizing IE1 motors may suffice for applications with less demanding energy standards, while IE3 motors are ideal for applications where energy savings are a priority.

IE1: Standard efficiency

IE2: Improved efficiency

IE3: Premium efficiency

Motor Type | Efficiency Class |

IE1 | Standard |

IE2 | High |

IE3 | Premium |

What are the benefits of using IE2 and IE3 motors?

The principal advantages of opting for IE2 and IE3 motors include not only energy savings but also longer operational life and reduced carbon footprint.

Explore more insightful articles like this one – we have plenty more for you to discover here !

Lower energy costs

Reduced environmental impact

Improved overall efficiency

Investing in IE2 and IE3 motors not only fosters sustainability but also contributes to significant cost savings in the long run.

Comments