What Are Linear Actuators And How Do They Work?

- Xie

- Jul 28, 2025

- 8 min read

Understanding the Basics of Linear Actuators

Linear actuators function as essential devices that convert rotary motion into linear motion. They play a crucial role in automating processes across various industries, providing precise control of movement. By employing electrical, hydraulic, or pneumatic mechanisms, these actuators deliver reliable performance, making them invaluable in applications ranging from manufacturing to robotics. Understanding the intricacies of how linear actuators function can significantly enhance operational efficiency and innovation.If you have any questions or are interested in our products, feel free to contact us

How Do Linear Actuators Work?

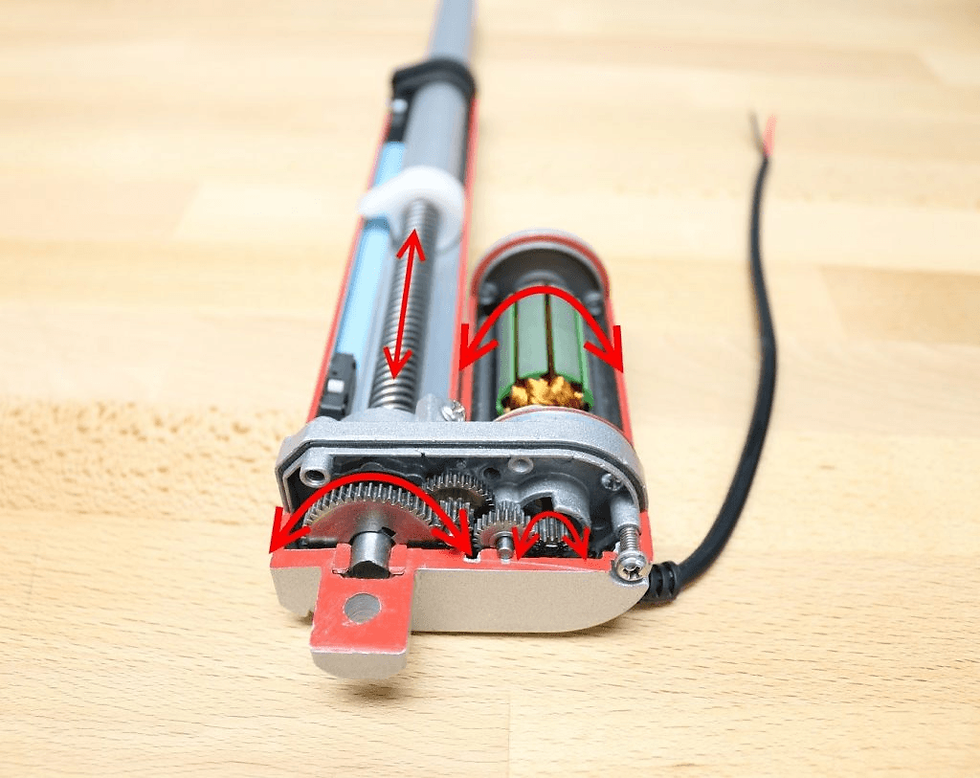

Linear actuators function by using a power source to create motion in a straight line. This can be achieved through various methods, including motors that drive a screw mechanism or the application of pressurized fluid in hydraulic systems. The specialized design allows for controlled movement, enabling the actuator to push or pull objects with remarkable accuracy and strength.

Applications of Linear Actuators

From automotive to healthcare, the applications of linear actuators are vast and varied. Industries leverage their functionalities for automation, providing seamless solutions for tasks that require consistent and reliable linear movement.

Robotics and automation

Medical devices

Aerospace technologies

Industrial machines

Actuator Type | Power Source | Applications |

Electric | Electricity | Robotics, Automation |

Hydraulic | Fluid Pressure | Industrial Machinery |

Pneumatic | Compressed Air | Medical Devices |

Benefits of Using Linear Actuators

The linear actuators function provides numerous benefits, including increased efficiency, precision, and flexibility in operations. Their ability to operate in diverse environments, coupled with ease of integration into various systems, makes them an attractive choice for many applications.

High reliability

Ease of maintenance

Enhanced control

The seamless operation and adaptability of linear actuators empower innovation across multiple sectors, transforming the way we approach automation.

Explore more insightful articles like this one – we have plenty more for you to discover here!

How Linear Actuators Enable Motion Control

Linear actuators are essential components in various fields, facilitating precise motion control. Their primary function is to convert rotational motion into linear displacement, enabling machines and systems to perform specific tasks efficiently. This functionality is crucial in robotics, automation, and manufacturing, where accuracy and speed are paramount. Understanding how linear actuators function allows industries to optimize processes and enhance productivity.

Components of Linear Actuators

Linear actuators typically consist of three main components: a motor, a lead screw, and a nut. The motor powers the lead screw, which converts the rotational energy into linear motion through the nut. This assembly provides the necessary force and control to achieve accurate positioning. The versatility of linear actuators lies in their ability to be tailored for different applications, from simple push/pull mechanisms to complex multi-axis systems.

Types of Linear Actuators

There are several types of linear actuators available in the market, each suited for specific applications. The most common types include electric, pneumatic, and hydraulic actuators. Each type has its advantages and drawbacks, making it essential to select the right actuator based on project requirements. For instance, electric actuators offer high precision, while pneumatic actuators can achieve rapid movement.

Electric Actuators

Pneumatic Actuators

Hydraulic Actuators

Ball Screw Actuators

Understanding the different types of linear actuators can greatly enhance operational efficiency. By selecting the most suitable type, one can increase the longevity and effectiveness of the machinery it powers.

Actuator Type | Advantages | Disadvantages |

Electric | High precision and control | Limited force output |

Pneumatic | Fast operation | Less precise |

Hydraulic | High force output | More maintenance required |

Applications of Linear Actuators

Linear actuators find applications across various sectors, enhancing efficiency in different machines. They are used in robotics for precise movements, in automation systems for assembly lines, and in healthcare for mobility devices. The growing significance of automation and smart technology ensures that their function remains integral to future innovations.

Explore more insightful articles like this one – we have plenty more for you to discover here !

Robotics

Manufacturing

Healthcare

Automated furniture

"Understanding the linear actuators function is key to leveraging their full potential in design and operation."

Applications That Rely on Linear Actuator Efficiency

Linear actuators function as essential components in various applications, enhancing operational efficiency and precision. From industrial automation to home automation systems, these devices transform rotational motion into linear movement, enabling tasks to be performed with accuracy. Their integration in sectors such as healthcare, automotive, and aerospace showcases their versatility and pivotal role in modern technology.

Healthcare Devices

In healthcare, linear actuators function in hospital beds, prosthetics, and surgical equipment, where they provide precise adjustments and movements. For example, automated beds allow for easy positioning of patients, improving comfort and care. The reliability of these actuators directly impacts patient outcomes and operational efficiency in medical facilities.

Automotive Applications

Within the automotive industry, linear actuators function to control various components, from adjusting seats to deploying spoilers. Their efficiency ensures that movements are swift and accurate, enhancing both vehicle performance and user experience. This technology plays a crucial role in the trend toward automation and smart vehicles.

Robotics

Home Automation

Manufacturing

Application | Function |

Healthcare | Patient positioning, prosthetics adjustment |

Automotive | Seat adjustment, automated systems |

Robotics and Manufacturing

Robotics and manufacturing are two burgeoning fields where linear actuators function extensively. These actuators enable robots to perform tasks with remarkable precision, ensuring quality control and efficiency in production lines.

Precision Agriculture

Aerospace

Consumer Electronics

The effectiveness of linear actuators in varying applications underlines their significance across sectors, enabling innovation and efficiency in everyday technology.

The Role of Linear Actuators in Automation

Linear actuators function as essential components in the automation landscape. Their primary role is to convert rotational motion into linear motion, facilitating various automated tasks across numerous industries. These devices contribute significantly to efficiency, precision, and repeatability, making them invaluable for modern automated systems. More importantly, they pave the way for advanced automation solutions that enhance productivity.

Key Applications of Linear Actuators

Linear actuators find a broad spectrum of applications, from robotics to manufacturing. In manufacturing, they assist in assembly lines, allowing machines to perform repetitive tasks with accuracy. In robotics, they enable robotic arms to execute precise movements required for delicate operations. Their versatility in application underscores their significance in the automation field.

Here is our homepage

Types of Linear Actuators

Linear actuators are available in various types, each tailored for specific functions. Common types include electric, hydraulic, and pneumatic actuators, each offering distinct advantages. Understanding the different types helps in selecting the right actuator for a particular automation task.

To meet the ultimate in efficiency and responsiveness in modern applications, many engineers and designers are turning to more specialized powertrains. If you're looking for a drive solution that combines speed and stability, the Speed-focused Motor is the ideal choice. It not only improves overall operating efficiency, but also demonstrates superior acceleration and precise control in mission-critical applications.

Electric Actuators

Hydraulic Actuators

Pneumatic Actuators

Type | Advantage |

Electric | High precision |

Hydraulic | High force output |

Pneumatic | Fast operation |

Choosing the Right Linear Actuator

When selecting linear actuators, it's vital to consider factors such as load capacity, speed, and required precision. The right choice can greatly influence the efficiency of the overall system in which they are deployed.

In many applications where high load capacity is required, high speed is not enough. A drive solution with strong torque output is the key, and the Torque -focused Motor is designed to cope with high loads and high resistance environments, and maintains a stable and strong power output at low speeds, which is widely used in industrial automation, heavy machinery, and lifting and lowering systems in the smart home.

Load Capacity

Speed

Precision

"Understanding the Linear Actuators function and their application can transform automation processes in any industry."

Benefits of Using Linear Actuators in Engineering

Linear actuators play a crucial role in engineering applications, providing precise movement control essential for automation processes. The linear actuators function effectively in various settings, from manufacturing to robotics, offering efficiency and reliability. By converting rotational motion into linear motion, these devices significantly enhance operational capabilities across multiple industries.

Precision and Control

One of the most significant benefits of linear actuators is their ability to provide high precision and control over movement. This feature is particularly valuable in applications where accuracy is paramount, such as in surgical machinery or aerospace systems. The linear actuators function with minimal backlash, allowing for smooth transitions and enhanced operational effectiveness.

Space Efficiency

Linear actuators are designed to be compact, making them ideal for applications with limited available space. Their space-saving designs enable integration into tight configurations without sacrificing performance. This flexibility allows engineers to maximize the potential of their systems while ensuring that every inch of workspace is utilized effectively.

Enhanced speed and efficiency

Reduced operational noise

Minimal maintenance requirements

Application | Benefit |

Aerospace | High precision capability |

Manufacturing | Increased operational efficiency |

Medical | Robust reliability |

Cost-Effectiveness

Investing in linear actuators often leads to reduced operational costs due to their long lifespan and low maintenance. This aspect makes them an attractive option for many engineering projects, yielding a higher return on investment over time.

Long-lasting performance

Lower power consumption

Budget-friendly options

"The integration of linear actuators revolutionizes engineering design and implementation, making processes smarter and more efficient."

In many applications where high load capacity is required, high speed is not enough. A drive solution with strong torque output is the key, and the Torque -focused Motor is designed to cope with high loads and high resistance environments, and maintains a stable and strong power output at low speeds, which is widely used in industrial automation, heavy machinery, and lifting and lowering systems in the smart home.

Future Trends in Linear Actuator Development

As technology evolves, the linear actuators function is becoming increasingly refined, leading to innovative applications across various industries. Modern linear actuators are not just about motion; they are now integral to enhancing automation processes. Their capability to operate under different conditions, coupled with advancements in materials and design, allows for significant improvements in efficiency and reliability.

Integration with Smart Technologies

One of the most exciting trends is the integration of linear actuators with smart technologies. The incorporation of IoT enables these devices to provide real-time feedback, improving the linear actuators function in precision applications. This not only enhances performance but also opens avenues for predictive maintenance, reducing downtime significantly.

Sustainable Designs

Another significant trend is the move towards sustainability in actuator development. Manufacturers are exploring eco-friendly materials and energy-efficient designs. This not only addresses environmental concerns but also optimizes linear actuators function by reducing operational costs. Businesses are becoming more conscientious of their ecological footprints, driving companies to innovate sustainably.

Smart integration for real-time feedback

Energy-efficient designs to reduce operational costs

Use of eco-friendly materials

Enhanced precision in applications

Trend | Description |

Smart Technologies | Real-time feedback through IoT integration |

Sustainability | Use of eco-friendly materials and designs |

Conclusion

The future of linear actuators is bright, with continual advancements promising enhanced performance and sustainability. Embracing these innovations can dramatically improve operational efficiency.

Stay updated with technological advancements

Focus on sustainable practices in procurement

"The evolution of linear actuators is a testament to the power of innovation in modern engineering."

Common Questions About Linear Actuators and Their Function

Linear actuators are vital components in various systems, functioning to convert rotary motion into linear motion. Their role is essential in applications ranging from automation to robotic mechanisms. Understanding how linear actuators function helps ensure proper integration into your projects. These devices can be electrically powered, hydraulically operated, or driven by pneumatic systems, each offering unique advantages and applications.

How Do Linear Actuators Work?

Linear actuators function by utilizing a mechanical system that produces movement. The motion typically occurs through a screw drive, rack and pinion, or another mechanical mechanism, allowing for precise control. This can be achieved through either open-loop or closed-loop control systems, where feedback mechanisms play a role in accuracy and efficiency in operation.

What Are the Key Applications of Linear Actuators?

Linear actuators find use in numerous industries, including manufacturing, healthcare, and robotics. They assist in tasks like positioning equipment, opening and closing valves, and moving robotic arms. Their versatility makes them indispensable for enhancing productivity and precision in various functions.

Automated machinery

Medical devices

Robotics

Automated doors

Understanding the various applications aids in selecting the right actuator for your needs. Here’s a comparison of common actuator types:

Type | Advantages | Disadvantages |

Electrical | High precision and easy control | Limited force in some cases |

Hydraulic | High force output | Requires hydraulic fluid |

What Should You Consider When Choosing a Linear Actuator?

When selecting a linear actuator, it’s crucial to assess various factors such as load capacity, speed requirements, and environmental conditions. This ensures you choose a device that will meet your project specifications effectively.

Load capacity

Speed and stroke length

Environmental exposure

"Choosing the right actuator can significantly enhance your project's efficiency and effectiveness."

Comments